Every year, businesses have to climb newer and larger digital mountains as technological development advances to unseen heights. They must also undergo various transformation processes to adapt to these new climates.

In 2024, consumers anticipate a certain level of product availability, transparency, and delivery timeframes. Digital transformation in the supply chain enables companies to enhance their production, distribution, and delivery procedures while meeting these growing expectations. Once you find all the ins-and-outs of the process and get the right solution that works for your business, the difference becomes apparent almost instantly—improved data exchange, real-time visibility, and data-driven decision-making for the entire chain.

Now, let’s examine digital transformation in the supply chain in greater detail. We’ll dissect the digital supply chain transformation process, and also highlight the advantages backed by real-life examples.

How Digital Transformation Benefits Supply Chain

Through digital transformation in the supply chain, we can understand the process of integrating digital technology into every aspect of a business to radically alter how you run, and how you provide value to clients. The implementation sphere can vary from high-tech healthcare digital solutions to AI boosting your e-commerce business.

The main goal of supply chain digital transformation is to use new technologies to fundamentally optimize both your business approach and customer experience. Based on our rigorous research, the most stand-out advantages of digital supply chains are gathered below.

Reduce Costs

Businesses can lower acquisition costs by integrating digital tools that help automate repetitive tasks, reduce manual errors, and optimize resource usage. Real-time data and predictive analytics enable better inventory management, minimizing overstock and shortages, which reduces holding and operational costs. Enhanced visibility across the supply chain prevents disruptions, lowers transportation expenses, and improves supplier collaboration, driving down overall costs.

Enhance Decision-Making

The decision-making process is more rapid and efficient with the help of emerging disruptive digital supply chain technologies like artificial intelligence, big data, and the Internet of Things. These technologies also increase operational efficiency by using continually updated data for predictive analytics. Businesses may optimize the management of their stocks and supplies while enhancing their agility and responsiveness by relying on dependable, pertinent, and real-time data flows.

Create Digital Threads

A digital thread is a communication system that connects data across a product’s lifecycle. It plays a key role in supply chain digital transformation by offering real-time insights and enhancing traceability. This flow of information between your company, suppliers, and customers improves operations, reduces inefficiencies, and drives innovation. It also promotes closer collaboration, boosting productivity and strengthening relationships within the supply chain.

Digital threads, while still a relatively new concept, are being successfully implemented by several companies. For instance, Vestas, a major wind turbine manufacturer, has integrated a digital thread to boost its product sustainability. By linking data throughout the product’s life cycle, from design to service, Vestas can optimize material use, minimize waste, and offer customers more transparent carbon footprint information.

VCST, a top automotive supplier, has also adopted a digital thread to connect data from IoT devices and product lifecycle management (PLM) systems. This digital transformation has empowered VCST to speed up product development, enhance quality control, and shorten time-to-market.

Improve Efficiency and Automation

Digital tools, such as AI, robotics, and IoT, automate manual processes like inventory management, order fulfillment, and tracking. This leads to faster and more accurate operations, reducing human error and freeing up resources for more strategic tasks.

For example, BengalFox’s digital transformation case demonstrates how manual, repetitive tasks can significantly hinder shipping operations. By partnering with Redwerk to develop a custom iOS app, they were able to automate their order processing workflow and reap substantial benefits. The app dramatically improved efficiency, reducing order processing time from 15 seconds to just 3 seconds while minimizing the risk of errors.

Enhance Visibility and Transparency

Real-time tracking of goods, materials, and shipments using IoT sensors and advanced analytics improves visibility across the entire supply chain. This transparency helps companies respond quicker to disruptions and better manage inventory levels.

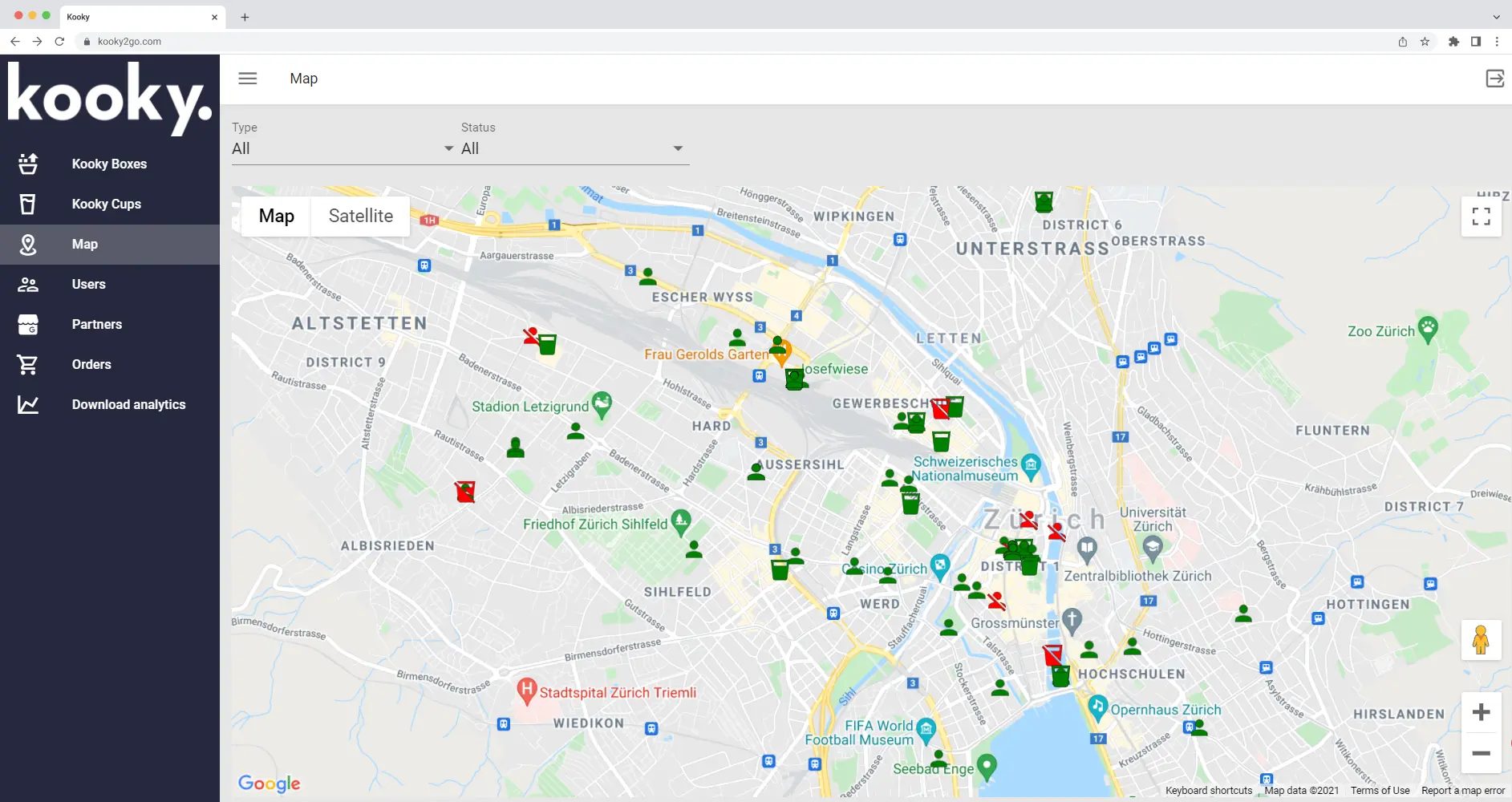

We have a perfect supply chain digital transformation case study to prove this point. Our Redwerk specialists have implemented an innovative software ecosystem for the Kooky green solution business that helps to organize work, provide end-to-end project management visibility, and monitor payments, logistics, and inventory. The visibility and transparency benefit was exactly what Kooky was looking for.

Common Challenges and Effective Solutions

While digital transformation brings advantages to the supply chain, it’s important to acknowledge the potential challenges. Judging from our extensive experience in providing digital transformation services, businesses have to navigate issues such as integrating legacy systems with new technologies, ensuring data security, and overcoming resistance to change within their organizations. We have compiled a short list of challenges you may expect when going through digital transformation in the supply chain so they will not catch you off-guard. We’ve also provided quick tips on how to mitigate these challenges.

Overcoming Resistance to Change

Employees may be hesitant to adopt new technologies due to concerns about job security, fear of the unknown, or discomfort with altering established processes. This resistance can slow down or derail digital transformation in supply chain management efforts.

This can be avoided by fostering a culture of innovation, providing clear communication about digital transformation’s benefits, and offering training programs to help employees adapt to new tools and systems. Engaging people early and addressing their concerns is key to ensuring a smooth transition.

Filling In the Skill Gaps

As the latest technologies (such as AI, automation, and advanced analytics) are introduced, your current workforce may not have the new skills necessary for implementing those digital transformation tools. This gap in technical skills can slow down the adoption process and reduce the effectiveness of digital solutions.

It can be resolved by offering opportunities for training and growth, recruiting new employees with the requisite training, or forming alliances with technology suppliers offering the required experience. Ensuring that employees have the right skills is critical for maximizing the potential of digital transformation in supply chain operations.

Lack of Process Automation

Streamlining operations and fully benefiting from supply chain digitalization without automated processes can be challenging. It is hard to be productive, react quickly to market demands, and control market segmentation using manual processes because they are prone to mistakes, delays, and inefficiencies.

For instance, implementing AI-driven chatbots and digital communication platforms will help manage supplier interactions and streamline communication. It can also automate order confirmations, inquiries, and dispute resolutions.

Ensuring Data Privacy and Security

With increased connectivity, cloud-based systems, and real-time data sharing between businesses, sensitive information such as customer data, trade secrets, and transaction details becomes more vulnerable to cyber threats. Companies must implement robust cybersecurity measures, including encryption, secure access controls, and regular audits, to protect against data breaches and cyberattacks.

Additionally, adopting a document management system (DMS) can be beneficial for safekeeping sensitive information, such as paperwork for warehouse management, and exchanging it with carriers. In that case, not everyone who previously handled shipping documents can view their content because the DMS can only use one authentication for each user requesting access to records.

Controlling Expenses

The cost of implementing new technologies can be high. Nonetheless, the long-term advantages of enhanced productivity, better customer support, and competitive advantage outweigh the expense.

Explore every aspect of your business, from production to customer service, to understand where technology can make a real difference. By focusing on areas where technology can improve efficiency, reduce costs, or enhance customer satisfaction, you’re more likely to see a positive return on your investment in digital transformation.

Digital Supply Chain Technologies & Tools

Given our profound experience, backed by our meticulous research of the most recent digital transformation trends, we would like to highlight the strategies for integrating digital transformation into your business’s supply chain. There are three main areas of digital transformation in the supply chain that will elevate your efficiency, if followed through.

Unified Platforms

Upgrading out-of-date systems and tying diverse apps together with unified technology is a common first step in digital transformation. Every level of the supply chain is more visible thanks to integrating various systems, data, and processes into a single cohesive framework. This lowers bottlenecks and boosts productivity across a range of functions.

Here are some examples of how unified platforms work within a digital transformation process:

- ERP Systems (Enterprise Resource Planning). Platforms like SAP or Oracle integrate procurement, manufacturing, inventory, and distribution, providing real-time data across departments.

- Supply Chain Management (SCM) Platforms. Tools like IBM Sterling or Kinaxis offer end-to-end visibility, enabling seamless coordination between suppliers, manufacturers, and distributors.

- Logistics Platforms. Systems like Freightos or Project44 unify shipping, tracking, and logistics management, optimizing delivery and reducing delays. If these don’t suit your needs, consider custom logistics software development.

These platforms provide smoother operations and better collaboration across the supply chain.

Artificial Intelligence and Automation

Digital transformation is greatly aided by automation. Workers can prioritize higher-priority jobs by using automated technologies to complete repetitive or manual operations with little human input. By removing the chance of human error, the technologies can increase accuracy while handling data.

Every aspect of supply chain management can benefit from the use of artificial intelligence and other automated technologies, from tracking goods movements to predicting purchasing patterns. To make sure that the correct numbers are used in purchases throughout your supply chain, you can automate data gathering and invoice processing.

Artificial intelligence enables organizations to make better informed decisions by collecting and analyzing large amounts of data without the need for human participation. Thanks to tools like natural language processing, AI can converse with customers and comprehend data or questions.

Data Analytics

For supply chain management to undergo a digital transformation, data analytics are a must. Gaining insight into customer expectations and supply chain delays is essential to developing adaptability and resilience. The more data you have, the quicker is your reaction, giving you a head start among your competitors.

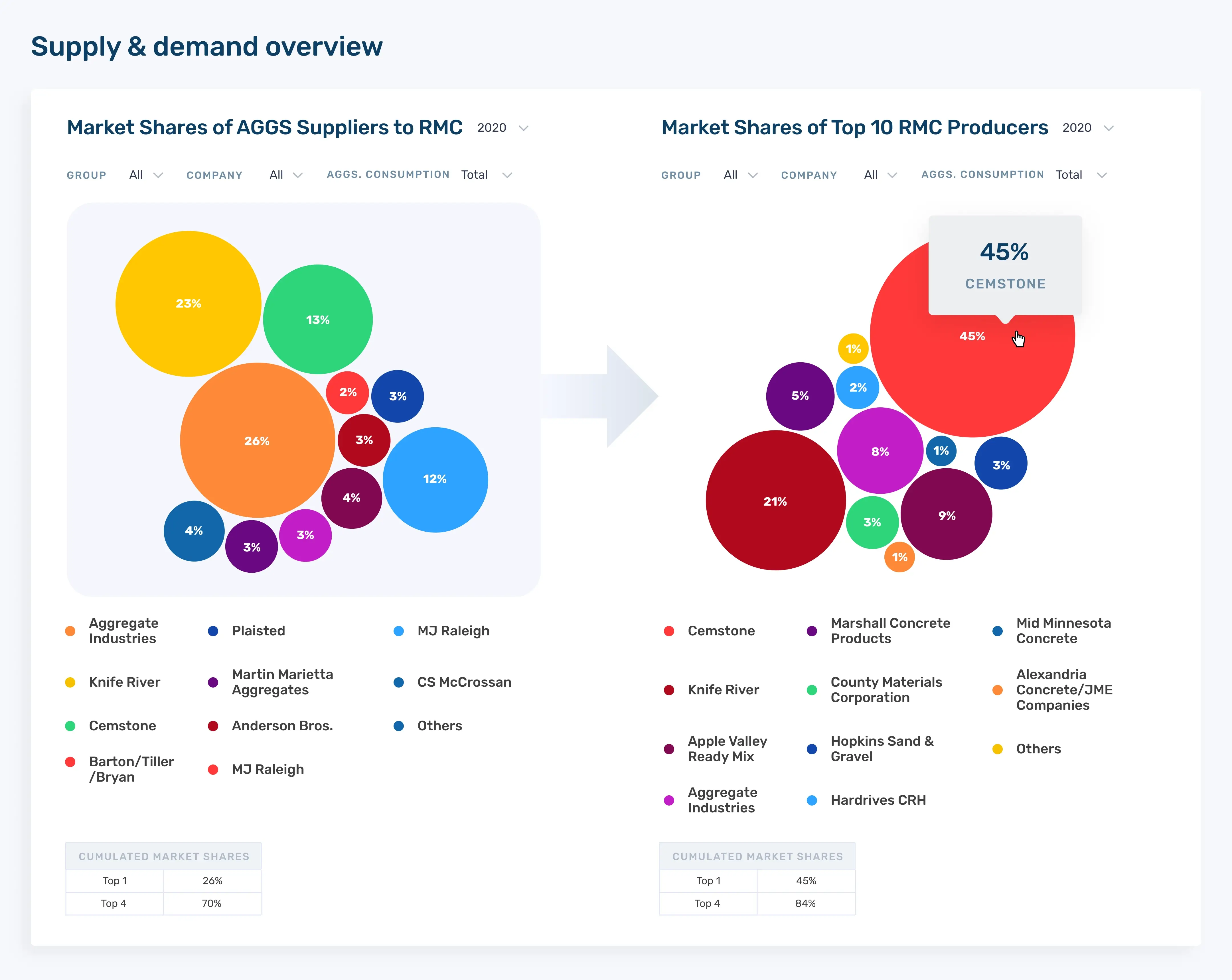

Your company can assess the data it has collected to improve operations. Workers can make the best decision possible by using data dashboards and other visualization tools, which make the information easily available. For example, Redwerk helped MarketBee, a consulting firm specializing in construction materials, replace spreadsheets and outdated apps used by aggregate producers with a robust data analytics solution. This empowered their clients to visualize market trends, compare competitors, and identify growth opportunities more effectively.

Real-Life Examples of Supply Chain Transformation

Numerous real-life examples, including global leaders such as Amazon, Unilever, and Walmart, prove the efficiency of implementing these steps in your digital transformation process. Let’s look a little closer at each case and how they’ve boosted their profit margins by adjusting to today’s challenges.

Amazon

One of the best examples of a business modernizing its supply chain is Amazon. The e-commerce global leader has automated its warehouse operations with cutting-edge digital solutions built on robots, machine learning, and artificial intelligence. Faster delivery times, less human error, and greater efficiency are the outcomes.

Additionally, Amazon has created their own streaming platform, Amazon Prime, and expanded into cloud services, becoming the world’s leading provider of infrastructure and cloud computing services.

Unilever

Global consumer products giant Unilever has changed how it does business to build a supply chain that is more effective and sustainable. With the use of digital twin technology, the company has produced a virtual supply chain duplicate. Unilever can now decrease waste and make better judgments by simulating and analyzing various scenarios. According to Unilever, this technology has improved the efficiency of its supply chain overall and helped it lower its carbon impact as a bonus.

Walmart

One of the biggest retailers in the world has integrated digital transformation with tailored marketing tools to improve inventory management. Their customized strategy enabled a real-time inventory system that tracks inventory levels and forecasts demand using AI and Internet of Things sensors. Walmart has been able to save a large amount of money by reducing understocking and overstocking. Walmart has also improved its logistics through digital transformation, employing drones and driverless cars for deliveries.

Supply Chain Transformation with Redwerk

Redwerk uses innovative approaches for digital transformation solutions to give businesses a head start. We tackle a wide range of industries, from e-government to manufacturing, and provide custom services like public works software and supply chain management software. Take a quick peek at some of the options:

- Transportation management software

- Inventory management system

- Customer relationship management system

- Product lifecycle management software

- Quality management software

- Market research software

Those are only a tiny part of what Redwerk has to offer. We have around two decades of industry experience, showcased in our extensive portfolio, giving us the skill and knowledge to deal with challenges and to provide our clients with straightforward, easy, and tailored services.

Summary

Digital transformation in the supply chain revolutionizes how businesses operate by integrating advanced technologies like real-time data analytics, automation, and unified platforms. It improves efficiency, reduces costs, enhances decision-making, and increases visibility across the supply chain, allowing businesses to respond quickly to market changes.

Even if the shift comes with challenges like change resistance, high costs, or lack of automation, the long-term benefits of optimized operations and improved customer satisfaction make it a necessary step for businesses aiming to stay competitive in a fast-evolving market.

To achieve digital transformation goals, businesses often need a reliable software development partner to provide services or consulting. If you’re looking for one, contact Redwerk to book a free, non-binding consultation and kick-start your transformation process.

FAQ

What is the significance of digital transformation in supply chain management?

Digital transformation in supply chain management is critical because it enables firms to leverage artificial intelligence (AI), robotics, the Internet of Things, and other technological advancements to improve operations, cut costs, and increase visibility.

What is the most challenging aspect of the digital transformation of the supply chain?

Implementing digital transformation in the supply chain presents a number of challenges, including the high cost of technology, the requirement for highly qualified specialists, worries about data security, and opposition to change. However, with the proper preparation, guidance, and risk management, these difficulties can be solved.

What are the benefits of digital transformation in supply chain management?

Supply chain stakeholders can gain a competitive edge in the market, as well as higher efficiency, accuracy, and customer satisfaction through digital transformation. Additionally, it gives companies fresh chances to innovate their supply chain procedures.

What role will digital transformation play in supply chain management in the future?

Artificial intelligence, machine learning, blockchain, and the Internet of Things are predicted to be the technologies driving supply chain management’s digital transformation in the future. The supply chain industry will be able to operate more creatively, accurately, and efficiently thanks to these technologies, which will boost consumer happiness and company performance.

See how we helped BengalFox

automate warehousing routines and reduce order processing from 15 to 3 seconds